DISPATCH

I met Nobuhiro Hayashi and Yukie Kaku during my second week of work at TYK. They are very friendly and lively people with whom I have exchanged and laughed a lot. Hayashi-san and Kaku-san are part of the TC Sleeve team and work mainly in one of the large warehouses in the R&D center. Nobuhiro Hayashi is someone very kind and very smiling. He has worked at TYK for nine years. He is 43 years old and comes from Toki, a small town near Tajimi, where he lives with his family in a traditional house. Hayashi-san loves martial art movies (Jackie Chan, Jean-Claude Van Damme) and racing movies. He is also passionate about sport. He does it almost every evening after work and has practiced Kenpô for nine years and Karate for four years. Doing Krav Maga (self-defense sport) myself, we talked a lot while laughing about our fighting techniques. Yukie Kaku is a 30-year-old young woman who speaks good English and does not like having photos taken with her in it. She is originally from Ôita on the island of Kyûshû and enjoys reading and playing video games. She was always ready to give me explanations on the (japanese alphabet) and very friendly. She has worked at TYK for six years.

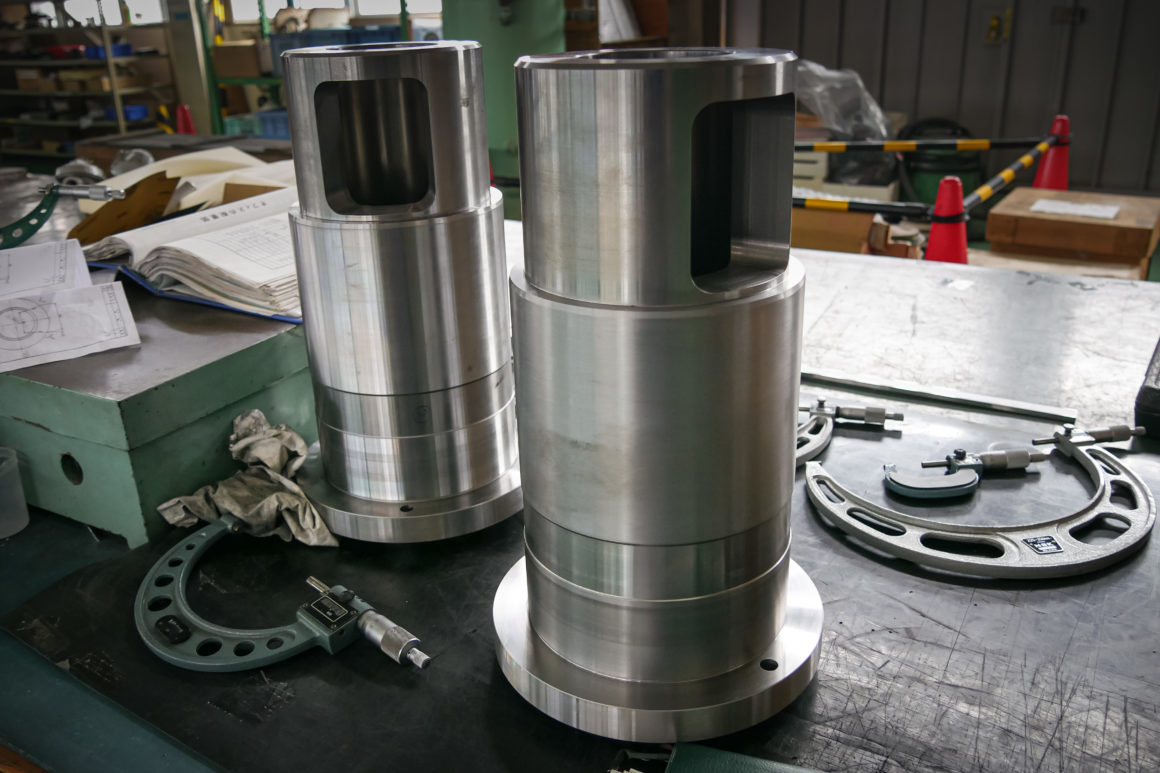

TC Sleeves are tools used in the casting or rolling processes. They are designed in titanium and ceramic composite and die-cast. They provide low thermal conductivity, excellent resistance to erosion by aluminum alloy and excellent resistance to abrasion.

Much of Hayashi-san’s job is to take care of the TC Sleeve manufacturing process. In summary, the process consists of mixing the composite and creating the molding, making it compact by cold isostatic pressing and then making it solid by treatment with Argon. Following this, the frame is finalized and cleaned and subjected to a heat treatment. Some parts of the product are then cut and welded. In addition to these steps, there are many steps to check for size and strength.

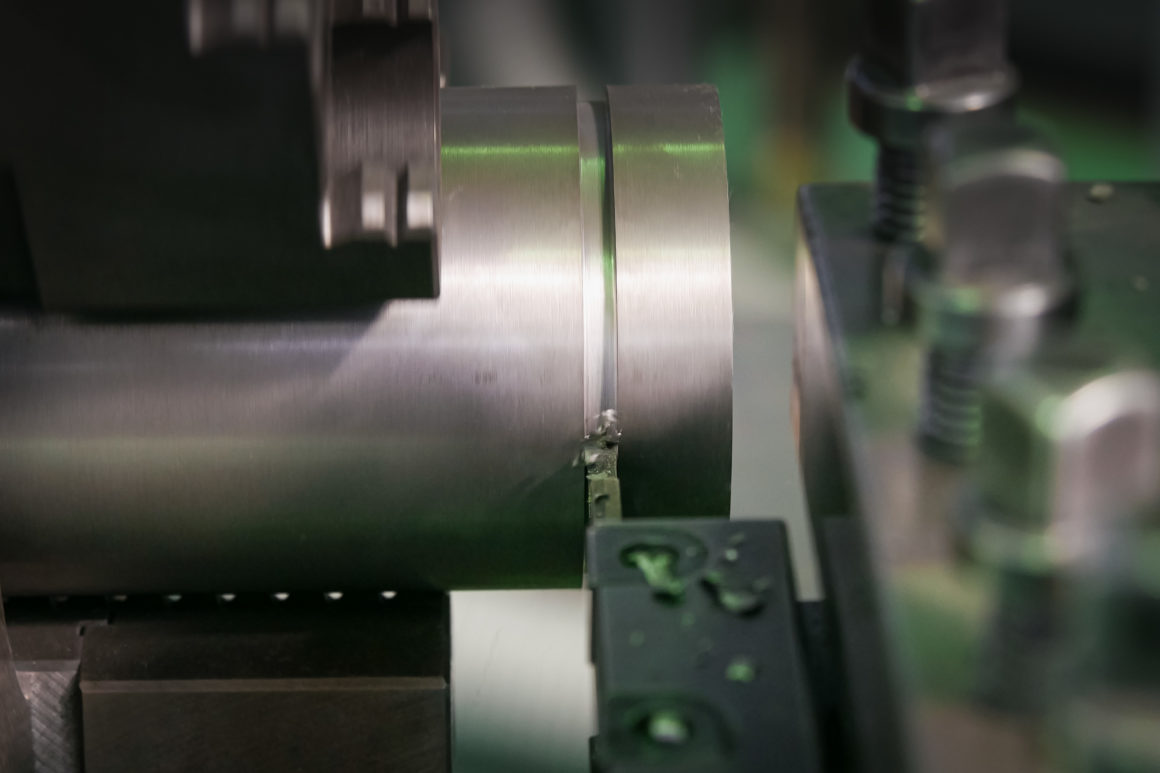

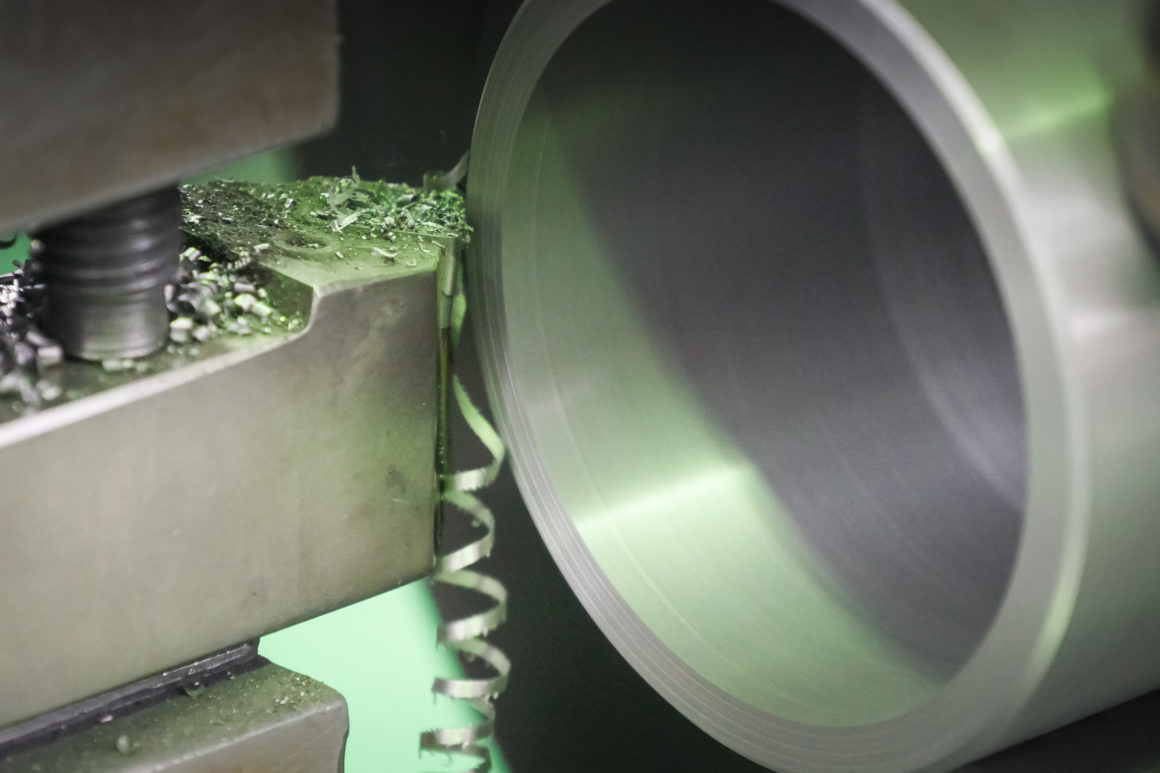

The main machines on which Hayashi-san and Kaku-san work are cutting machines. They are entirely manual, three machines for an average age of 45 years of exercice. Cutting machines called “Sen Ban” in Japanese make it possible to cut and file very precisely. Hayashi-san and Kaku-san use them to finalize the TC Sleeve framework and cut samples. They run almost continuously all day. The cutting machines operate entirely manually, with different levers. Hayashi-san manipulates the levers with impressive dexterity and speed.

Kaku-san, when she is not working on the “Sen Ban”, takes care of cleaning and checking the size of the TC Sleeve during the creation process, as well as performing various tests on the samples cut from the frame.

Sound of machines

Below, first row, left: Hayashi-san is creating the molding of a TC Sleeve. The titanium composite is introduced into a mold and then distributed compactly using a vibrating support, so as to leave no empty space in the mold and therefore avoid design flaws. Right: Kaku-san is in charge of the TC Sleeve heat treatment. These are placed in a large oven where they will undergo the process for several hours.

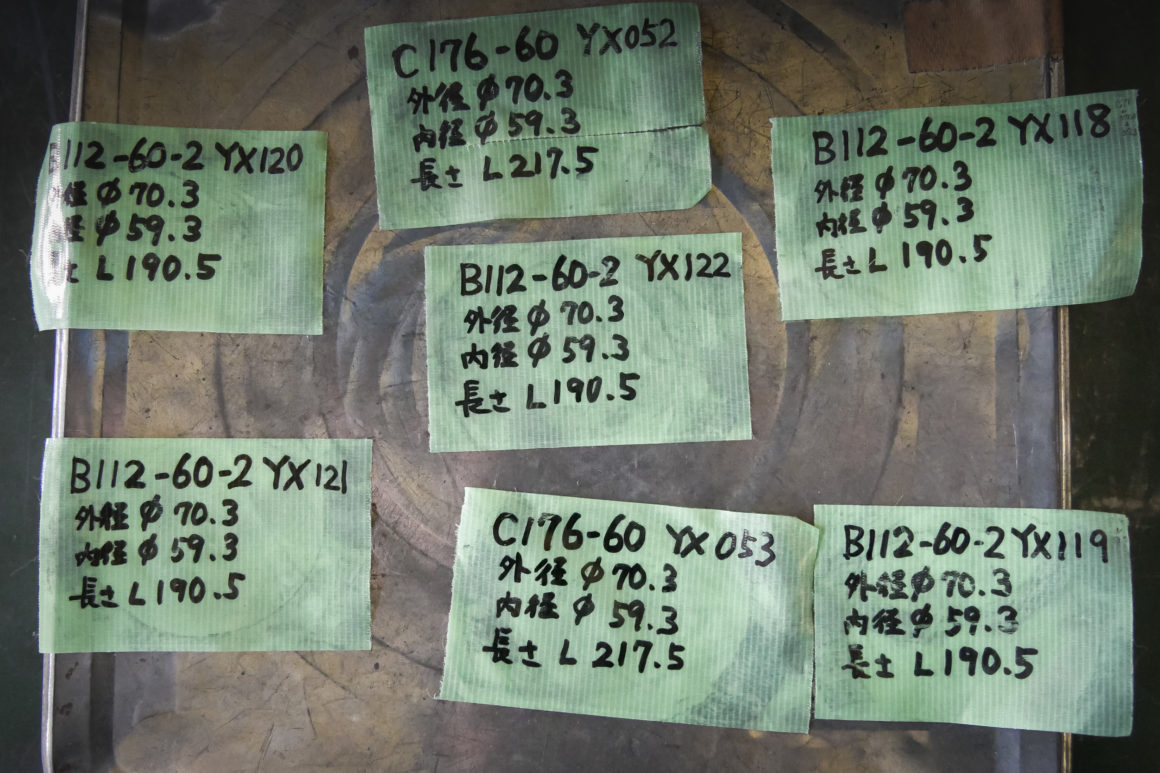

Second line: Hayashi-san checking the frame dimensions of a TC Sleeve being finalized. It is meticulous work since it is necessary to respect the prescribed dimensions. In one day, Hayashi-san can finalize around ten TC Sleeves.

Cutting machines constantly generate small debris called “kiriko” (“kiri” means “cut” and “ko” means “ends”). You have to be careful not to get hurt with it. On average, the machines are fully cleaned 2 to 3 times a week.

The work on cutting machines uses a lot of oil. And it is forbidden to wear gloves because they can get caught in the wheels and cause accidents. So hands are quickly covered with oil and small debris of titanium. Hayashi-san’s hands are marked by years of work.

From each TC Sleeve being finalized is taken a sample. These will undergo various tests (pressure, resistance, water absorption, etc.) in order to detect any problems.

The work done by Hayashi-san and Kaku-san is manual, repetitive and not very diversified. But the good understanding between the two members of the team and the possibility of experimenting in the creation process in order to obtain TC Sleeves corresponding to the different needs, however, offer to them a relatively interesting job. In any case, Hayshi-san and Kaku-san seemed to me to be motivated and energetic during their working day. Which was not the case of some other team members.

During my week with Hayashi-san and Kaku-san I participated in the whole process of creating TC Sleeve. Below, I am monitoring the progress of cutting a frame. It was a very interesting week, full of exchanges and good humor. Hayashi-san, Kaku-san, arigatôgozaimashita!